Automotive

Our in-house tooling capabilities, broad range pf part sixes, advanced quality systems and strategic manufacturing location allow Cumberland to meet your most aggressive time to market and cost demands from initial design through production.

Our current part and assembly portfolio include:

- Custom Color Interior and Exterior Trim

- High Gloss “Piano Black” applications

- Functional IP components and sub-assemblies

- Audio System Speaker Grills

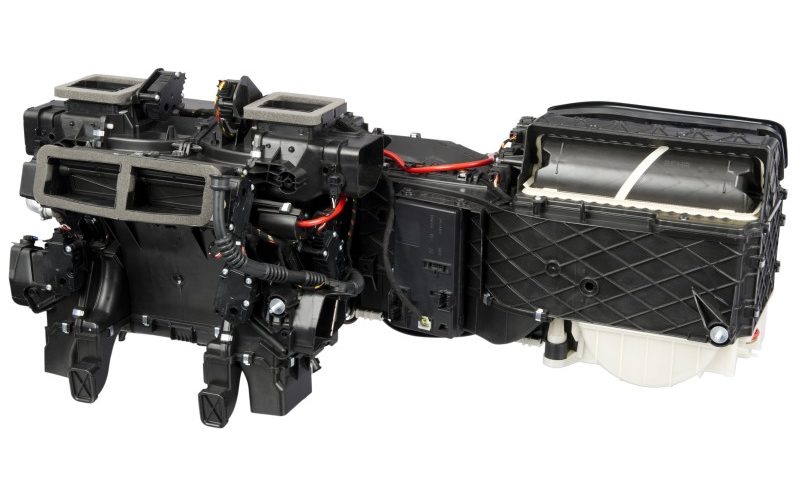

- Engine Cooling and HVAC Components / Assemblies

Renewable Energy

At Cumberland Plastic Solutions, we understand the critical performance and durability requirements of parts used in the renewable energy sector. Our components are designed to withstand fluctuating temperatures, weather conditions, and environmental stresses to ensure optimal performance over time.

We supply a wide range of products for solar energy applications, including component tiedowns, junction boxes, and inverter cases. These parts are often crafted from high-performance engineered resins like Polycarbonate, Polystyrene, and Polyethylene, chosen for their exceptional weather resistance and moldability. With strict tolerance specifications, we ensure that each part is rigorously tested and validated to meet the demanding standards required for sustained functionality in the field.

Standby Generators

Standby Generator manufacturers count on Cumberland for the production of critical parts and sub-assemblies to produce their capable products. Our parts are required to perform under a wide range of temperature and weather conditions which contribute to the inherent reliability of our customers’ products.

Powersports

From ATVs and Side by Sides to Watercraft and Golf Carts, Cumberland produces high quality parts that perform in the most arduous of conditions. High Impact, UV Resistant, Custom Color parts and assemblies that are counted on for years by the vehicle owners.

Design, Tooling, Production and assemblies from one supplier, Cumberland Plastic Solutions.

Lawn & Garden

Cumberland Plastics supplies some of the most successful lawn and garden companies with a broad range of injection molded parts, tooling and sub-assemblies for functional engine components. These include Class A surface parts as well as structural and mechanical components.

Cumberland’s broad experience with resin performance and part design as well as UV testing helps support our customers through DFM and into production.

Building & Construction

Designing and producing critical injection molded parts that allow our customers to supply the highest quality, competitively priced products for both new construction and remodeling.

Cumberland’s capabilities include part design, resin selection, mold design and construction as well as custom packaging design and production.