Onshoring

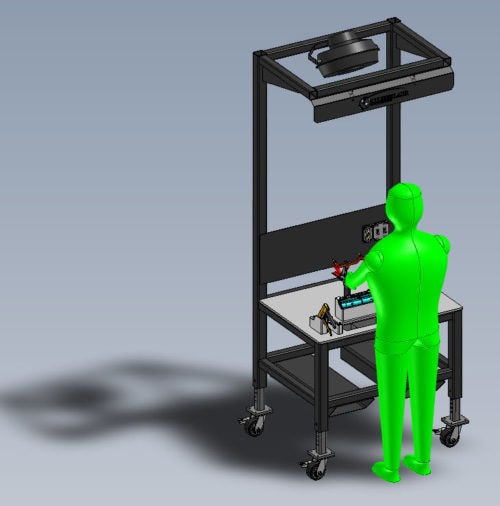

Seat Handle Assembly

Many of our customers followed the trend of offshoring over the past decades. In recent years, we have been engaged to bring production back onshore for several of our customers. Issues such as supply interruptions, shipping interruptions, consistency of quality, communication and true cost have driven our customers to find a domestic solution. We have worked with our customers to develop tooling, automated assembly equipment/processes to be able to provide a domestic production solution at a competitive price without the inherent risks associated with offshore production.

One such recent project was a Seat Handle Assembly that was being produced in China. We worked with our client to optimize the product design for manufacturing and manufactured a new injection mold capable of producing a much higher quality part. Our Product Development team designed an automated assembly station to significantly reduce the labor required to assemble the components thereby eliminating any benefit of LCC production. Our customer now receives a higher quality product from a domestic supplier at a comparable cost without all of the supply risks, quality and communication issues.

Tooling

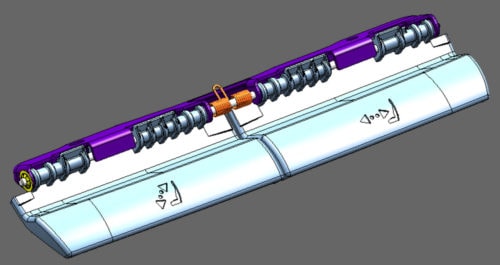

Structural Mounting Bracket

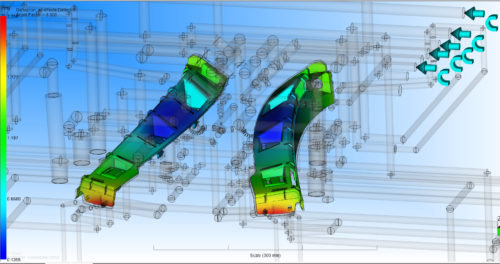

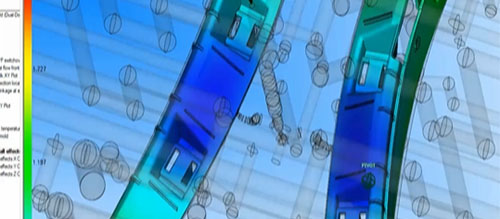

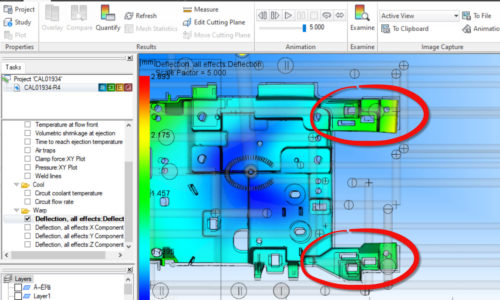

This part had some specific challenges. Gate location options were limited by part design. The resin used for this application was long-glass filled polypropylene. Due to limited available gate location options and part geometry, we knew that glass fiber orientation would be problematic in some areas of the part causing non-uniform shrinkage/warpage.

Moldflow® analysis was utilized to predict warp in the molded part prior to mold manufacture. The part model was then modified to incorporate 60% of predicted warpage in areas of concern. The mold design was updated to include inserts in these areas of the mold for ease of modification after first shots. The mold was manufactured with these features incorporated and an FOT trial was performed.

Molded parts were measured to correlate actual results with the predicted warpage. A DOE was prescribed to evaluate improvements based on process parameter changes. Parts from this DOE were measured, and the optimal process parameters were selected.

Part models were then modified to compensate for observed warpage and mold components were manufactured to reflect the revised data. Another trial was conducted using the optimized parameters and parts from this trial were measured and found to be within spec.

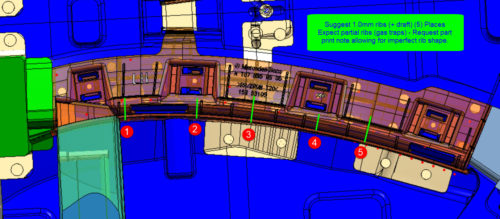

Wheel Arch Bracket

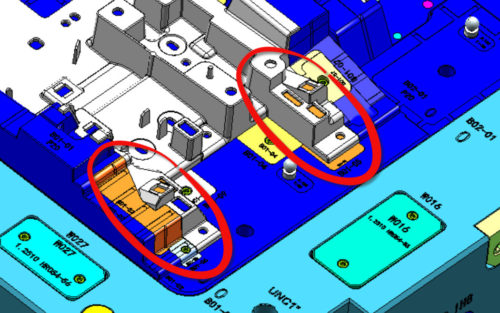

Our customer ordered an engineering change that significantly altered the structure of the part. Cumberland implemented the E.C. and due to the structural changes, significant warpage was observed causing problems with final assembly at the customer’s site.

We performed a new Moldflow® analysis and found that the results correlated with the measured warpage in the molded parts. Cumberland engineering staff studied the part model and mold design to devise a part change that would meet the following criteria.

- Must improve or eliminate warpage without adversely affecting the fit or appearance of the part in vehicle position.

- Must be implemented in the existing tool without adversely affecting tooling life.

Cumberland created a new part model with structural ribs which were designed to stabilize the part during the cooling process to reduce warpage. This solution was capable of being implemented within the existing tool thereby saving the customer the significant cost of manufacturing new cavity and core blocks. A new Moldflow® analysis was performed to evaluate the effect on warpage.

After this analysis, the engineer made minor modifications to the part model to improve the stability of the part. At this time, another iteration of warp analysis was performed and further improvements to predicted warpage were observed. The improved part model was then sent to the customer for approval.

Cumberland’s engineering team evaluated the mold design and devised a plan to optimize the cooling system. Our in-house mold shop then applied these improvements to the mold. After implementation of these changes, we have been able to consistently produce parts which met the customer’s specifications.

Automation

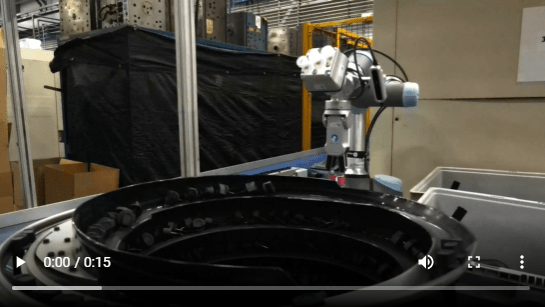

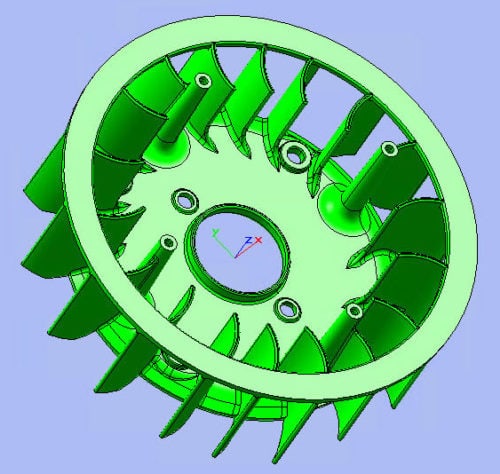

Lawn & Garden Flywheel

The customer was experiencing ongoing short shot issues with a previous supplier, and due to the complexity of the tool and resin, a stable process monitoring system could not be established.

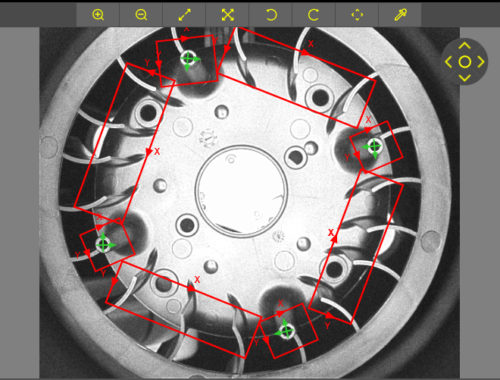

Cumberland engineering evaluated a multitude of vision systems in order to detect the defective condition and reject the part without ever making it to the customer. A binary filter was used to create good contrast between the features to be inspected and the background. Using this filtered image, a counting tool was used to count the number of fan blades. The minimum edge width was adjusted to detect a short shot defect on a fan blade. A blob tool was then used to detect a short shot on the outer edge of the part.

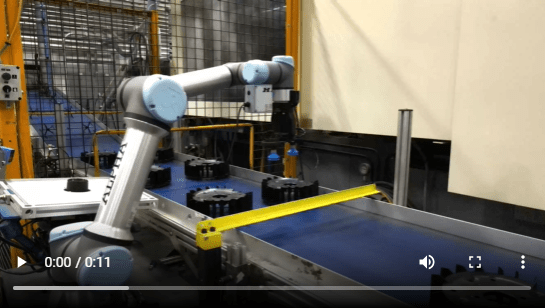

A collaborative robot picks the part and presents it to the camera for inspection. Upon successful inspection, the part is passed and packaged. If a part fails vision inspection, the collaborative robot will dispose of the rejected part.

Since implementation, there have been zero parts received at the customer with this condition.

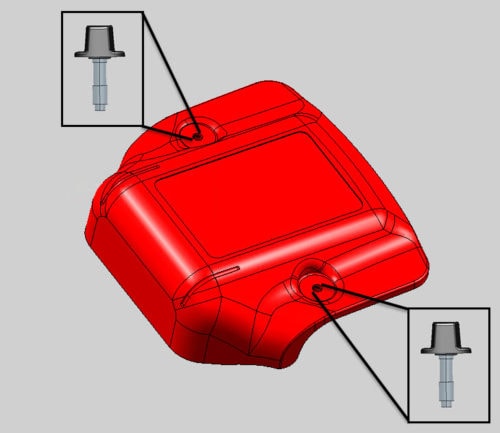

R11.5 AC Cover

This air cleaner cover has an annual volume of over 500,000 units and was a perfect candidate for automating the assembly process.

The part has two press fit knobs that are installed so that the customer can easily place and screw down on their assembly line. The value-added services provided by Cumberland eliminated an additional assembly operation at the customer’s assembly line, and by automating the process in line with the molding of the part, we are able to provide cost savings and zero quality issues to the customer.