Cumberland Plastic Solutions (CPS) has a world class injection molding operation located in Opelika AL, housed in a state of the art 215,000 SQFT facility, situated on 40 acres of land located directly off the I-85 interstate.

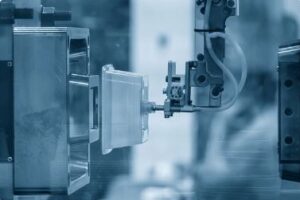

CPS runs on a 24/5 production schedule across 3 shifts with weekends available for additional capacity. CPS has 200 full time employees with 43 precision injection molding machines ranging from 90 Ton up to 1,500 Ton presses.

CPS has expertise in a wide range of thermoplastics and engineered resins including but not limited to PP, ABS, POM, ASA, PA 6 & 6/6, PC, PC-ABS, PMMA, TPO/TPE, with an extensive supply base.

CPS’s core competencies include:

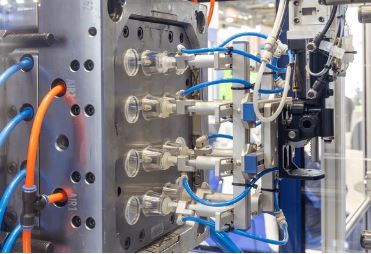

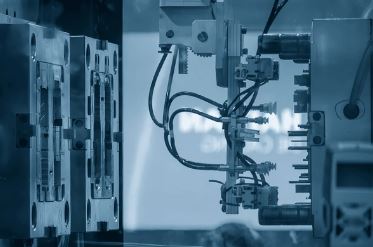

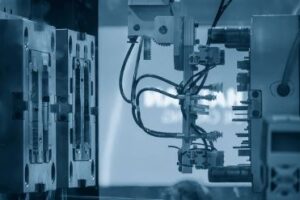

- 1K & 2K injection molding

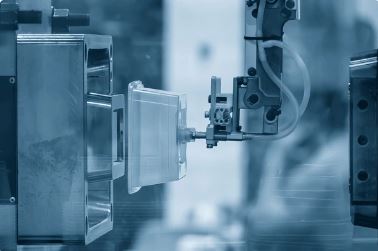

- Class A Parts including interior and exterior trim applications

- Mold in color – custom color matching (pre-colored & masterbatch). In house color/gloss meters with dedicated light booth

- High gloss tooling and molding

- High precision / tight tolerance and complex parts

- HVAC under the hood applications

- Complex sub-assemblies with a variety of secondary operations

Value-add secondary operations include:

- Welding (Ultrasonic, Vibration, Hot-Plate)

- Heat Staking

- Over Molding

- Insert Molding

- Hot Stamping

- Leak testing

- Sub-Assemblies from simple to fully automated poke yoke / vision systems

- Packaging design (returnable and expendable)

- Quality lab with CMM, 3D scanner, Optical Comparator and in-house PPAP capabilities

- Fully EDI Capable